Call Us

Call Us

+91-22-62700204 Email

Email

enquiry@calicometal.com

Call Us

Call Us Email

Email

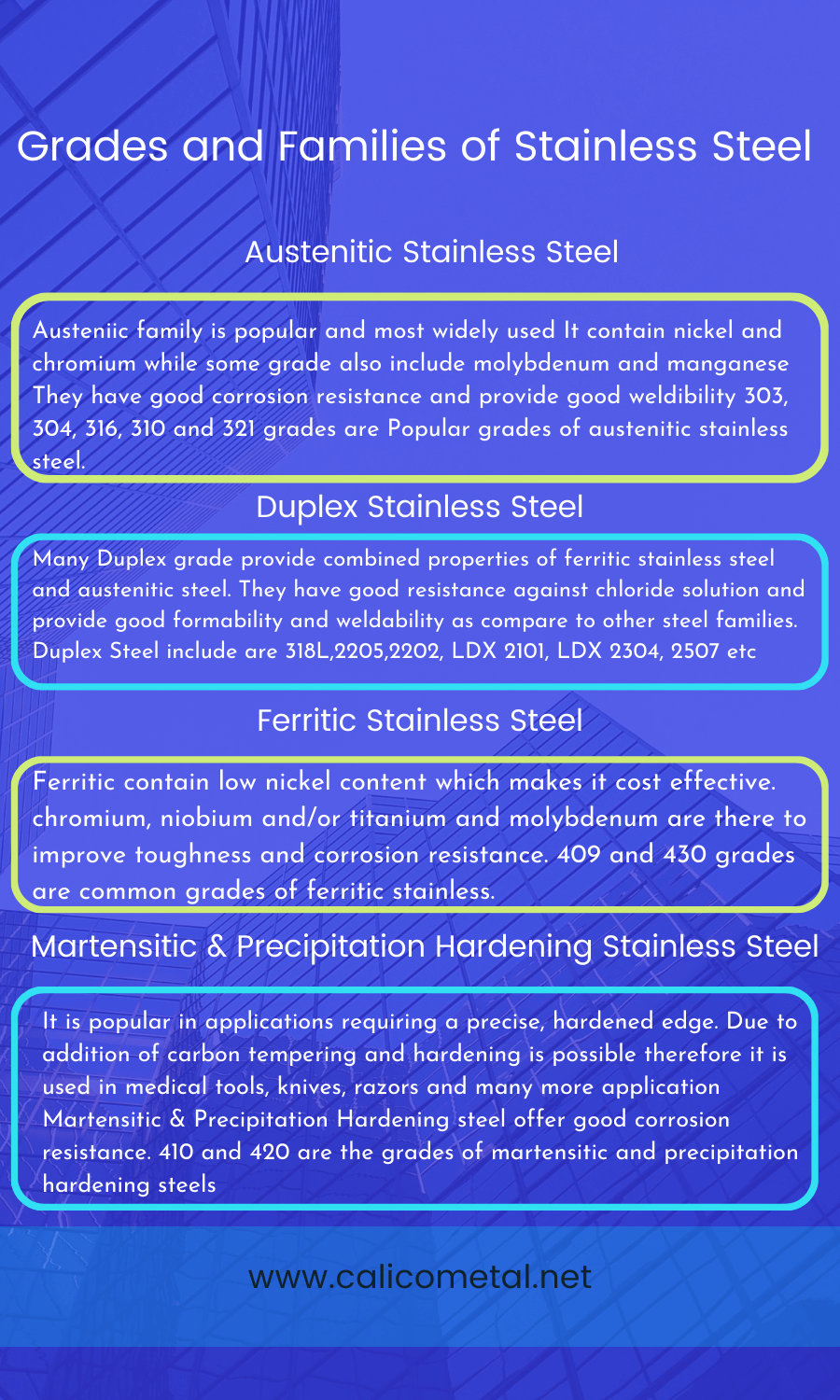

Have you ever wondered about the different "Grades and Families of Stainless Steel" and why they're so essential in modern applications? Stainless steel is an incredibly versatile material, and its various grades and families offer unique properties that make them perfect for a wide range of applications.

In this comprehensive guide, we will dive deep into the world of stainless steel, exploring its fascinating history, the key characteristics of each family, and how these properties impact their uses in everyday life. From the austenitic stainless steel in your kitchen appliances to the duplex stainless steel used in chemical processing plants, you'll discover how these remarkable materials have revolutionized industries across the globe.

As you read on, you'll gain invaluable insights into the factors that influence the selection of stainless steel grades, including corrosion resistance, mechanical properties, and cost considerations. You'll also learn about real-life examples of stainless steel applications, showcasing the material's incredible versatility and the wide range of industries it serves.

I. Introduction

Stainless steel is an extraordinary material that has revolutionized various industries, thanks to its unique properties and characteristics. In this blog post, we will explore the different Grades and Families of Stainless Steel and how they impact modern applications. But first, let's take a brief look at the history of stainless steel.

A. Brief history of stainless steel

The discovery of stainless steel dates back to the early 20th century when Harry Brearley, a metallurgist from Sheffield, England, accidentally stumbled upon this remarkable material while researching ways to improve the wear resistance of gun barrels. His discovery of chromium's ability to create a thin, protective oxide layer on the surface of steel marked the beginning of the stainless steel era. Since then, various grades and families of stainless steel have been developed to cater to the specific needs of diverse industries.

II. Families of Stainless Steel

There are five main families of stainless steel, each with its unique set of properties and characteristics. In this section, we will discuss each family in detail, covering their common grades, applications, and uses.

1. Characteristics and properties

Austenitic stainless steels are the most widely used family of stainless steel, accounting for about 70% of total stainless steel production. These steels are non-magnetic and have a face-centered cubic (FCC) crystal structure. They exhibit excellent formability, weldability, and corrosion resistance due to their high chromium and nickel content.

2. Common grades (e.g., 304, 316)

The most common austenitic stainless steel grades are 304 and 316. Grade 304, also known as 18/8 stainless steel, contains 18% chromium and 8% nickel, making it highly resistant to corrosion and oxidation. Grade 316, on the other hand, has an additional 2-3% molybdenum content, which enhances its resistance to chloride corrosion and makes it suitable for marine and chemical processing applications.

3. Applications and uses

Austenitic stainless steels are used in various applications, such as kitchen appliances, sinks, cutlery, architectural cladding, and chemical equipment. Their excellent formability and weldability make them ideal for forming complex shapes and structures.

1. Characteristics and properties

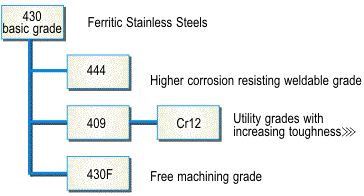

Ferritic stainless steels have a body-centered cubic (BCC) crystal structure and are magnetic. They contain 10.5-30% chromium but little or no nickel, which makes them less expensive than austenitic grades. However, their corrosion resistance, formability, and weldability are generally lower compared to austenitic stainless steels.

2. Common grades (e.g., 430, 446)

Some common ferritic stainless steel grades include 430 and 446. Grade 430 contains 16-18% chromium, making it suitable for moderately corrosive environments. Grade 446, with its higher chromium content (23-27%), offers better high-temperature oxidation and creep resistance.

3. Applications and uses

Ferritic stainless steels are commonly used in automotive exhaust systems, heat exchangers, and decorative trim due to their magnetic properties and lower cost.

1. Characteristics and properties

Martensitic stainless steels are magnetic and have a body-centered tetragonal (BCT) crystal structure. They contain 11.5-18% chromium and up to 1.2% carbon, which makes them hardenable through heat treatment. As a result, they offer a unique combination of high strength, hardness, and wear resistance.

2. Common grades (e.g., 410, 420)

Some common martensitic stainless steel grades are 410 and 420. Grade 410 contains 11.5-13.5% chromium and offers moderate corrosion resistance. Grade 420, with its higher carbon content (0.15-0.4%), provides improved hardness and wear resistance, making it suitable for cutlery and surgical instruments.

3. Applications and uses

Martensitic stainless steels are typically used in applications requiring high strength, hardness, and wear resistance, such as cutlery, surgical instruments, bearings, and valve components.

1. Characteristics and properties

Duplex stainless steels have a mixed microstructure of austenite and ferrite, resulting in a combination of the best properties of both austenitic and ferritic stainless steels. They exhibit high strength, excellent corrosion resistance, and good weldability. Moreover, they offer better resistance to stress corrosion cracking and pitting corrosion compared to austenitic grades.

2. Common grades (e.g., 2205, 2507)

Common duplex stainless steel grades include 2205 and 2507. Grade 2205 contains 22% chromium, 5% nickel, and 3% molybdenum, making it suitable for applications in aggressive environments. Grade 2507, also known as super duplex stainless steel, has even higher chromium (24-26%), nickel (6-8%), and molybdenum (3-5%) content, providing exceptional corrosion resistance and strength.

3. Applications and uses

Duplex stainless steels are used in various applications, such as chemical processing plants, desalination plants, and offshore platforms, where high strength and excellent corrosion resistance are essential.

| Grade | EN NO/UNS | Type | Approx Composition | ||||||

|---|---|---|---|---|---|---|---|---|---|

| r | NI | Mo | N | Mn | N | u | |||

| 2101 LOX | 1.41621 S32101 | Lean | 21.5 | 1.5 | 0.3 | 0.22 | 5 | ||

| DX2202 | 1.40621 S32202 | Lean | 3 | 2.5 | 0.3 | 0.2 | 1.5 | ||

| RDN 903 | 1.44821 S32001 | Lean | 20 | 1.8 | 0.2 | 0.11 | 4.2 | ||

| 2304 | 1.43621 S32304 | Lean | 23 | 4.8 | 0.3 | 0.10 | |||

| 2205 | 1.44621 S31803 S32205 | Standard | 22 | 5.7 | 3.1 | 0.17 | |||

| 2507 | 1.44101 S32750 | Super | 25 | 7 | 4 | 0.27 | " | ||

| ron 100 | 1.45011 S32760 | Super | 5 | 7 | 3.2 | 0.25 | 0.7 | 0.7 | |

| Ferrlnox 255/Uranus 2507Cu | 1.4507/ S32520 S32550 | Super | 5 | 6.5 | 3.5 | 0.25 | 1.5 | ||

1. Characteristics and properties

Precipitation-hardening stainless steels are a unique family of stainless steel that can be hardened through heat treatment, similar to martensitic stainless steels. However, they offer better corrosion resistance, comparable to that of austenitic grades, due to their higher chromium and nickel content.

2. Common grades (e.g., 17-4PH, 15-5PH)

Popular precipitation-hardening stainless steel grades include 17-4PH and 15-5PH. Both grades contain 17% chromium and 4% nickel, but 15-5PH has a lower carbon content, resulting in improved weldability and stress corrosion cracking resistance.

3. Applications and uses

Precipitation-hardening stainless steels are used in aerospace, marine, and oil and gas industries, where a combination of high strength, good corrosion resistance, and excellent mechanical properties is required.

| Alloy Group | Austenitic | Duplex | Ferritic | Martensitic | Precipitation Hardening |

|---|---|---|---|---|---|

| Magnetic Response | Generally No | Yes | Yes | Yes | Yes |

| Work Hardening Rate | Very High | Medium | Medium | Medium | Medium |

| Corrosion Resistance | High | Very High | Medium | Medium | Medium |

| Hardenable | By Cold Work | No | No | Quench & Temper | Age Harden |

| Ductility | Very High | Medium | Medium | Low | Medium |

| High Temperature Resistance | Very High | Low | High | Low | Low |

| Low Temperature Resistance | Very High | Medium | Low | Low | Low |

| Weldability | Very High | High | Low | Low | High |

When selecting a stainless steel grade for a specific application, several factors need to be considered. These factors include corrosion resistance, mechanical properties, formability and weldability, heat treatment requirements, and cost considerations. By evaluating each factor carefully, the most suitable stainless steel grade can be chosen to meet the specific requirements of the application.

To further illustrate the versatility of stainless steel, we will now explore some real-life examples of applications where each family of stainless steel plays a crucial role.

A. Austenitic stainless steel in food processing equipment

Austenitic stainless steel, particularly grades 304 and 316, is commonly used in food processing equipment due to its excellent corrosion resistance, formability, and weldability. This makes it an ideal material for components such as mixing tanks, storage containers, and conveyor systems in the food and beverage industry.

B. Ferritic stainless steel in automotive exhaust systems

Ferritic stainless steel, especially grade 409, is widely used in automotive exhaust systems, including mufflers, catalytic converters, and exhaust manifolds. Its good corrosion resistance, high-temperature oxidation resistance, and cost-effectiveness make it suitable for these applications.

C. Martensitic stainless steel in cutlery and surgical instruments

Martensitic stainless steel, particularly grade 420, is the material of choice for cutlery, knives, and surgical instruments due to its excellent hardness, wear resistance, and ability to maintain a sharp edge. Its moderate corrosion resistance also makes it suitable for these applications.

D. Duplex stainless steel in chemical processing and desalination plants

Duplex stainless steel is commonly used in chemical processing plants and desalination plants due to its exceptional corrosion resistance, especially in chloride-rich environments, and high strength. Its resistance to stress corrosion cracking and pitting corrosion makes it ideal for components such as heat exchangers, pressure vessels, and piping systems.

E. Precipitation-hardening stainless steel in aerospace and marine applications

Precipitation-hardening stainless steels, like 17-4PH and 15-5PH, are often used in aerospace and marine applications where high strength, good corrosion resistance, and excellent mechanical properties are required. Examples of these applications include landing gear components, helicopter rotor blades, and fasteners in aircraft structures.

In this comprehensive guide, we have explored the different grades and families of stainless steel, their unique properties and characteristics, and the various factors affecting the selection of stainless steel grades. Understanding these aspects is crucial for making informed decisions when choosing the right stainless steel grade for specific applications. As innovations and developments in stainless steel technology continue to emerge, we can expect even more versatile and high-performance materials in the future.